Views: 0 Author: Site Editor Publish Time: 2025-10-07 Origin: Site

Bending aluminum pipe correctly is a critical skill for professionals working in industrial applications, particularly in compressed air systems, HVAC installations, and fluid transport networks. While aluminum pipes offer excellent corrosion resistance and lightweight properties, they require specific techniques and tools to achieve precise bends without compromising structural integrity. This comprehensive guide explores professional methods for bending aluminum pipe, essential equipment, industry standards, and best practices to ensure optimal results in commercial and industrial applications.

Aluminum pipe bending is the process of deforming straight aluminum tubing into curved or angled sections while maintaining the pipe's structural integrity and inner diameter. Professional aluminum pipe bending requires understanding material properties, appropriate tooling, and precise technique to prevent common issues like kinking, wall thinning, or ovalization.

When approaching an aluminum pipe bending project, professionals must consider several critical factors: the pipe's alloy composition, wall thickness, outer diameter, required bend radius, and the specific application requirements. For industrial systems, particularly Aluminum Pipe for Air Systems, maintaining consistent internal diameter throughout the bend is essential for ensuring proper flow rates and preventing pressure drops.

Professional aluminum pipe bending differs significantly from casual bending operations. It requires precision equipment, measurement tools, and often specialized training to ensure that the finished product meets industry standards and specifications. The techniques discussed in this article focus on methods used in industrial and commercial applications, particularly for compressed air systems, inert gas distribution, and other professional fluid transport applications.

Selecting the appropriate tools is crucial for successful aluminum pipe bending in industrial applications. Here's a comprehensive overview of professional-grade equipment used in the industry:

Rotary draw benders represent the industry standard for precision bending of aluminum pipes in professional settings. These machines work by clamping the pipe between a bend die and counter-pressure die, then rotating the bend die to create a smooth, controlled bend.

Key components of a professional rotary draw bender include:

Bend die (matching the pipe's outer diameter)

Counter-pressure die

Mandrel (optional, used to prevent pipe collapse)

Wiper die (reduces marking on the outer radius)

Pressure die (applies consistent force during the bend)

Rotary draw benders are ideal for creating precise, repeatable bends in aluminum piping systems where consistency is critical, such as in compressed air distribution networks.

For large-scale industrial applications, CNC (Computer Numerical Control) pipe benders offer unmatched precision and consistency. These automated systems allow for:

Programmable bend angles

Multi-plane bending capability

Consistent production of complex bend patterns

Minimal operator intervention

Digital documentation of bend specifications

CNC benders are particularly valuable for manufacturing components for aluminum compressed air piping systems where multiple identical units are required.

Roll benders (also called "three-roll benders") use three rollers positioned in a triangle formation to create gradual, sweeping bends in aluminum pipe. These machines are ideal for:

Creating large radius bends

Forming gentle curves in larger diameter pipes

Producing continuous radius bends

Manufacturing spiral coils from aluminum tubing

Roll benders are often used in specialized applications where large-diameter aluminum pipes require gentle curves rather than tight bends.

| Bender Type | Best For | Pipe Diameter Range | Precision Level | Relative Cost | Learning Curve |

|---|---|---|---|---|---|

| Rotary Draw | Tight precision bends | 1/4" - 3" | Very High | High | Moderate |

| CNC Bender | Production runs, complex patterns | 1/8" - 6"+ | Excellent | Very High | Steep |

| Roll Bender | Gradual curves, large diameters | 1/2" - 12"+ | Good | Moderate | Moderate |

| Hydraulic Bender | High force applications | 1/2" - 4" | Good | High | Moderate |

Professional operations typically invest in equipment that matches their specific aluminum pipe bending requirements, with many facilities maintaining multiple types of benders to address various project needs.

When working with aluminum pipes in industrial applications, several specialized techniques have become industry standards. The selection of the appropriate method depends on the specific requirements of the project, including bend radius, pipe diameter, and application specifics.

Cold bending is the most common method used for aluminum pipe in professional settings, particularly for compressed air systems. This technique involves bending the aluminum pipe at room temperature using specialized equipment.

Steps for professional cold bending:

Select the appropriate dies and tooling for the pipe diameter

Measure and mark the pipe according to specifications

Secure the pipe in the bender, ensuring proper alignment

Apply lubricant if required by the specific application

Execute the bend slowly and evenly to prevent material stress

Check the bend against specifications using measurement tools

Make any necessary adjustments to achieve required tolerances

Cold bending is preferred for aluminum compressed air piping installations because it maintains the material's structural integrity without introducing heat-related complications.

For applications requiring tight bend radii while maintaining precise internal dimensions, mandrel bending is the preferred technique. This method uses an internal support (mandrel) inserted into the pipe during the bending process.

Key considerations for professional mandrel bending:

The mandrel must be properly sized for the pipe's internal diameter

Correct positioning of the mandrel at the bend point is critical

Specialized lubricants are required to prevent material adhesion

The mandrel must be extracted carefully after bending

Post-bend inspection of internal dimensions is essential

Mandrel bending is particularly important for aluminum pipes used in compressed air systems where maintaining consistent internal diameter is crucial for system performance.

In some industrial applications involving larger diameter aluminum pipes, ram-style bending may be employed. This technique uses hydraulic force applied at strategic points to create controlled deformation.

Professional ram-style bending considerations:

Requires precise calculation of force requirements

Specialized fixtures to hold the pipe during bending

Multiple pressure points for complex bends

Advanced measurement systems to verify results

Often computer-controlled for repeatability

While less common than other methods, ram-style bending has specific applications in custom industrial installations where standard equipment cannot accommodate large-diameter aluminum pipe.

Professional aluminum pipe bending must conform to various industry standards and specifications, particularly for compressed air systems and industrial applications. Understanding and following these standards ensures system integrity, safety, and compliance.

The American Society of Mechanical Engineers (ASME) B31.3 standard covers process piping, including aluminum pipe installations. Key requirements include:

Minimum bend radius specifications based on pipe diameter

Wall thinning limitations (typically maximum of 10%)

Ovality tolerances (difference between maximum and minimum diameters)

Documentation requirements for bend verification

Material-specific considerations for aluminum alloys

Professionals working with aluminum pipe for compressed air systems must ensure compliance with these standards throughout the bending process.

The International Organization for Standardization (ISO) provides testing standards for metallic materials, including aluminum pipes. ISO 8491 outlines:

Test procedures for evaluating bend quality

Measurement techniques for determining compliance

Acceptance criteria for industrial applications

Reporting requirements for quality assurance

These standards are particularly relevant for aluminum compressed air piping systems where quality assurance documentation may be required.

Different industries have specific tolerances for aluminum pipe bending:

| Industry | Typical Bend Radius Requirement | Ovality Tolerance | Wall Thinning Limit |

|---|---|---|---|

| Compressed Air | 3× pipe diameter minimum | 8% maximum | 10% maximum |

| Aerospace | 4× pipe diameter minimum | 5% maximum | 8% maximum |

| Food & Beverage | 3.5× pipe diameter minimum | 7% maximum | 12% maximum |

| Pharmaceutical | 4× pipe diameter minimum | 5% maximum | 8% maximum |

Professional pipe benders must be familiar with the specific requirements of the industry they're serving to ensure compliance with all relevant standards.

Beyond basic techniques, professional aluminum pipe bending for industrial applications requires attention to several advanced considerations to ensure optimal system performance.

The specific aluminum alloy used significantly impacts bending behavior and results. Common alloys for industrial piping include:

6061-T6: High strength, excellent corrosion resistance, moderate formability

6063-T5: Excellent formability, good strength, superior surface finish

3003-H14: Excellent formability, moderate strength, good for complex bends

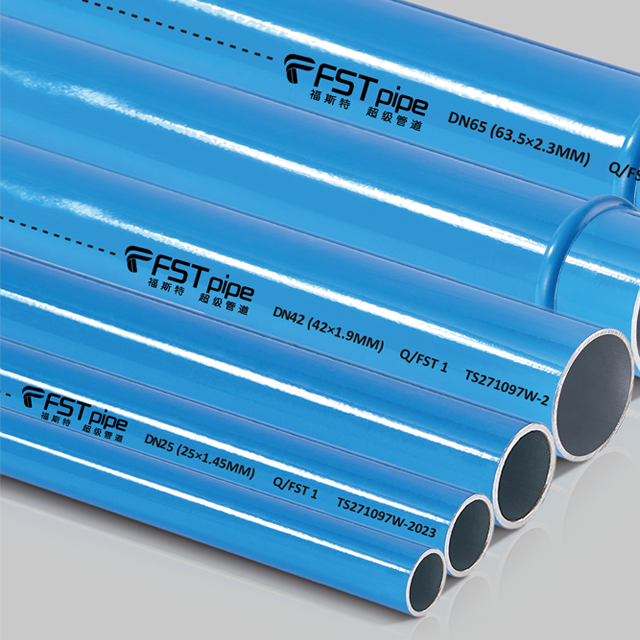

For Aluminum Pipe for Air Systems, alloy selection must balance pressure requirements, corrosion resistance, and formability. FSTpipe's aluminum air piping systems utilize optimized alloys specifically designed for compressed air applications, offering the ideal balance of these properties.

Professional aluminum pipe bending requires precise calculations, particularly for complex systems. Key calculations include:

Developed length (accounting for material stretch/compression)

Bend allowances based on material properties

Spring-back compensation factors

Clearance requirements for system integration

Stress analysis for high-pressure systems

Advanced software tools assist professionals in calculating these factors, ensuring precise results when bending aluminum pipe for complex industrial systems.

Professional aluminum pipe bending operations implement rigorous quality control procedures, including:

Pre-bend material inspection

Tool and die maintenance protocols

In-process measurement verification

Post-bend dimensional validation

Pressure testing of completed assemblies

Documentation of conformance to specifications

These procedures are critical when producing components for aluminum compressed air piping systems, where quality directly impacts system efficiency and operational costs.

Bent aluminum pipes serve various specialized functions across different industrial sectors. Understanding these applications provides context for the importance of proper bending techniques.

In compressed air systems, properly bent aluminum pipe plays a crucial role in system design and efficiency. Key considerations include:

Minimizing pressure drops through optimized flow paths

Reducing connection points by using bent sections

Creating ergonomic layouts for maintenance access

Accommodating thermal expansion through designed bends

Optimizing spatial requirements in facility layouts

FSTpipe's aluminum compressed air piping solutions incorporate precision bends to optimize system performance while reducing installation complexity and potential leak points.

Vacuum systems impose unique demands on bent aluminum pipe sections:

Higher collapse resistance requirements

Stricter ovality tolerances

Enhanced surface finish specifications

Special cleaning procedures post-bending

Specialized testing protocols

Professional aluminum pipe bending for vacuum applications requires attention to these specific requirements to ensure system integrity.

Beyond standard systems, bent aluminum pipe serves numerous specialized industrial functions:

Process cooling systems with custom routing

Instrumentation protection and support structures

Safety barrier systems with ergonomic designs

Visual management system frameworks

Equipment connection interfaces

These applications often require custom bending solutions tailored to specific facility requirements, highlighting the importance of versatile bending capabilities.

Even with proper equipment and techniques, challenges can arise when bending aluminum pipe. Professional pipe benders must be prepared to identify and address these issues.

Kinking represents one of the most common failures in aluminum pipe bending. Prevention strategies include:

Using appropriate bend radius for the material thickness

Employing mandrels for tight radius bends

Ensuring proper lubrication of contact surfaces

Applying consistent bending pressure throughout the process

Utilizing support fixtures for complex bends

When kinking occurs despite preventive measures, professional pipe benders must assess whether the component can be salvaged or must be replaced.

Wall thinning on the outer radius of a bend can compromise the structural integrity of aluminum pipe. Management techniques include:

Selecting appropriate bend dies for the material

Using compression techniques to feed material into the bend

Employing boost pressure systems on advanced benders

Monitoring wall thickness throughout the process

Specifying thicker initial wall thickness where appropriate

For high-pressure applications, wall thickness verification after bending is essential to ensure system safety and compliance with specifications.

Maintaining the roundness of aluminum pipe during bending is critical for flow characteristics, especially in compressed air systems. Control methods include:

Using properly sized mandrels

Employing wiper dies to support the outside of the bend

Applying appropriate pressure die force

Utilizing specialized tooling for thin-wall pipe

Implementing post-bend correction techniques when necessary

Professional aluminum pipe bending operations typically specify maximum ovality tolerances based on the specific application requirements.

Successful industrial aluminum pipe bending projects require comprehensive planning and systematic implementation. This structured approach ensures efficient execution and quality results.

Before any bending occurs, professional installers conduct thorough site surveys to determine:

Spatial constraints and routing requirements

Flow requirements and pressure specifications

Environmental conditions affecting material selection

Access requirements for installation and maintenance

Integration points with existing systems

This information forms the foundation for the bending plan and specification development.

Professional aluminum pipe installation projects rely on detailed bend plans that specify:

Precise measurements for each bend location

Required bend angles and radii

Orientation of bends relative to system layout

Sequence of bends for complex components

Quality verification checkpoints

These plans often include CAD drawings and may utilize 3D modeling for complex installations, particularly for aluminum compressed air piping systems where spatial optimization is critical.

After bending is complete, professional installations undergo verification procedures including:

Dimensional verification against specifications

Fit testing in assembled systems

Pressure testing to ensure system integrity

Flow testing to confirm performance characteristics

Documentation of compliance with all requirements

These steps ensure that the bent aluminum pipe components will perform as expected when integrated into the complete system.

For many industrial applications, particularly compressed air systems, partnering with a specialized provider offers significant advantages over attempting in-house bending operations.

Companies like FSTpipe offer comprehensive aluminum pipe system solutions that include:

Engineering expertise specific to the application

Optimized material selection for performance requirements

Factory-controlled bending for consistent quality

System-wide compatibility of components

Warranty coverage for the entire installation

Documentation for regulatory compliance

These benefits often outweigh the perceived advantages of in-house fabrication, particularly for critical systems where performance and reliability are paramount.

Professional aluminum pipe system providers typically offer customized design services that include:

On-site evaluation of requirements

3D modeling of proposed systems

Pressure drop calculations across the system

Energy efficiency optimization

Integration planning with existing infrastructure

Future expansion considerations

These services ensure that the aluminum pipe system, including all bent components, will meet both current needs and anticipated future requirements.

Beyond the bending itself, professional providers offer:

Trained installation teams familiar with the specific system

Proper handling procedures for aluminum components

Quality assurance during installation

System testing and commissioning

Ongoing maintenance support

Technical assistance for system modifications

This comprehensive approach ensures that the aluminum pipe system performs as designed throughout its operational life.

Q1: Can you bend aluminum tubing by hand?

A1: Professional-grade aluminum tubing used in industrial applications generally cannot be bent by hand without proper tooling. Attempting to do so typically results in kinking, ovalization, or structural weakness. For industrial applications, particularly in compressed air systems, professional bending equipment is essential to maintain the pipe's integrity and ensure system performance.

Q2: What is the easiest way to bend aluminum?

A2: For professional applications, a rotary draw bender with the appropriate dies and tooling represents the most reliable method for bending aluminum pipe. This approach provides consistent results, precise control over bend angles and radii, and minimizes the risk of pipe deformation. While various methods exist, professional installations demand the precision and reliability that comes with proper equipment.

Q3: Can you heat aluminum pipe to bend it?

A3: While aluminum can be bent using heat in some applications, this method is generally not recommended for professional industrial piping systems. Heating aluminum alters its metallurgical properties, potentially weakening the material and creating inconsistent wall thickness. For critical applications like compressed air systems, cold bending using professional equipment is the industry standard to maintain material integrity and system reliability.

Q4: Is it better to bend aluminum hot or cold?

A4: For industrial applications, particularly compressed air systems using aluminum pipe, cold bending is the preferred method. Cold bending preserves the aluminum's mechanical properties, maintains consistent wall thickness, and produces more predictable results. Hot bending introduces variables that can compromise system integrity and is generally avoided in professional installations where performance specifications must be met.

Q5: How do you prevent aluminum pipe from kinking when bending?

A5: Preventing kinks in aluminum pipe during bending requires several professional techniques: using an appropriate bend radius (generally at least 3 times the pipe diameter), employing properly sized mandrels for support, ensuring consistent bending speed, utilizing appropriate lubrication, and selecting the correct dies for the specific pipe diameter and wall thickness. For critical systems, bending should be performed by trained professionals using specialized equipment.

Q6: What is the minimum bend radius for aluminum pipe?

A6: The minimum bend radius for aluminum pipe depends on several factors including the alloy, wall thickness, and diameter. As a general industry guideline, the minimum bend radius should not be less than 3 times the outer diameter of the pipe. However, for specific applications like high-pressure compressed air systems, this may increase to 4 or 5 times the diameter to ensure optimal flow characteristics and structural integrity.

Q7: How does bending affect the structural integrity of aluminum pipes?

A7: Professional bending, when performed correctly, maintains the structural integrity of aluminum pipes while changing their shape. However, the bending process does introduce stress in the material, potentially thinning the outer wall and slightly compressing the inner wall. For industrial applications, these effects must be accounted for in the system design, particularly for high-pressure applications where wall thickness is critical to operational safety and performance.

Proper bending of aluminum pipe is a critical aspect of creating efficient, reliable industrial systems, particularly in compressed air applications. By understanding the professional techniques, tools, and considerations outlined in this guide, system designers and installers can ensure optimal performance and longevity of aluminum pipe installations.

For most industrial applications, partnering with experienced providers like FSTpipe delivers significant advantages through specialized expertise, optimized components, and system-wide integration. Their aluminum pipe for air systems incorporates professional bending techniques to create efficient, leak-free installations that optimize both performance and operational costs.

Whether undertaking in-house fabrication or working with specialized providers, adhering to industry standards and best practices for aluminum pipe bending ensures that the resulting systems will meet performance expectations and provide reliable service throughout their operational life.